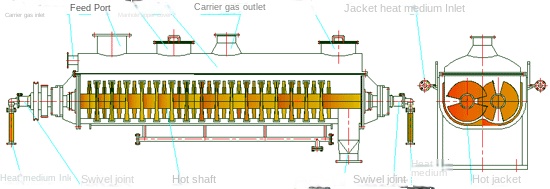

·Working principle

Hollow blade stirring dryer is an indirect heating low-speed stirring dryer that can operate continuously and belongs to high-efficiency and energy-saving drying equipment. There are two or four hollow rotating shafts inside the equipment, and wedge-shaped hollow blades are densely arranged on the hollow shafts. The heat medium flows through the blades through the hollow shafts. The flow channel inside the hot shaft is special and cleverly designed. The two shafts rotate in opposite directions, causing compression and relaxation between the shafts. With the help of wedge-shaped blades, the material is constantly flipped and stirred, updating the heating surface of the material and greatly improving the evaporation efficiency. According to the drying temperature, commonly used heat media include steam, thermal oil, hot water, and cooling water, which can complete unit operations such as drying, cooling, heating, and reaction.

·Equipment features

The wedge-shaped blade heat transfer surface has self-cleaning function

☆ The device has a compact structure, occupies a small area, and is easy to operate

☆ Fully sealed operation, minimal dust in the workshop, and low environmental pollution

☆ The outer wall of the equipment is equipped with an insulation layer, which has low energy consumption and a thermal efficiency of up to 95%

·Adapt to materials

☆ Environmental protection industry: dyeing factory sludge, municipal sludge, water treatment plant sludge, boiler ash, pharmaceutical factory waste, sugar factory waste, monosodium glutamate factory waste, etc

Petrochemical industry: polypropylene, polyethylene, polyvinyl chloride, polyphenylene sulfide, polyester, nylon, engineering plastics, acetate fiber, etc

☆ Chemical industry: Soda ash, activated carbon, calcium carbonate, white carbon black, titanium dioxide, barium sulfate, EDTA sodium salt, molecular sieve, kaolin, compound fertilizer

☆ Feed industry: distiller's grains, soy sauce residue, vinegar residue, fish meal, soybean meal, feed additives, apple pomace, bone based feed, biological sludge, etc

☆ Food industry: starch, cocoa beans, corn kernels, salt, milk powder, pharmaceuticals and intermediates

☆ Explosive Industry: Axial cooling medium can be used as an explosive cooling machine

·Structural schematic diagram

Keyword: